8-6 rubber slurry pump factory

Latest articles

Natural rubber is an excellent wear material when handling wet sand slurries. Its strength, resilience and cut resistance have a positive impact on the wear performance of slurry pumps.

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read MoreThe size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read MoreSlurry Pump

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read MoreWhat is Heavy Duty Slurry Pump?

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read MoreDredge Pump Features

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read MoreCentrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read MorePacking the box seal

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read MoreThe most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read More>Dredge pumps are a special category of pumps used in the dredging process. Dredging is the process of transporting submerged sediments (usually sand, gravel or rock) from one area to another. Dredging takes place in the shallow waters of lakes, rivers or seas for land reclamation, dredging, flood control, new harbours or expansion of existing harbours. The various industries that use dredge pumps are therefore the construction industry, mining, the coal industry and the oil and gas industry.

8-6 rubber slurry pump factory...

8-6 rubber slurry pump factory 【8-6 rubber slurry pump factory】

Read More

Popular articles

Latest articles

-

If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

-

- Pumping media where abrasive particles are present

-

What is the pump constructed of?

-

Discharge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

-

It is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

-

Vertical Slurry Pump

Links

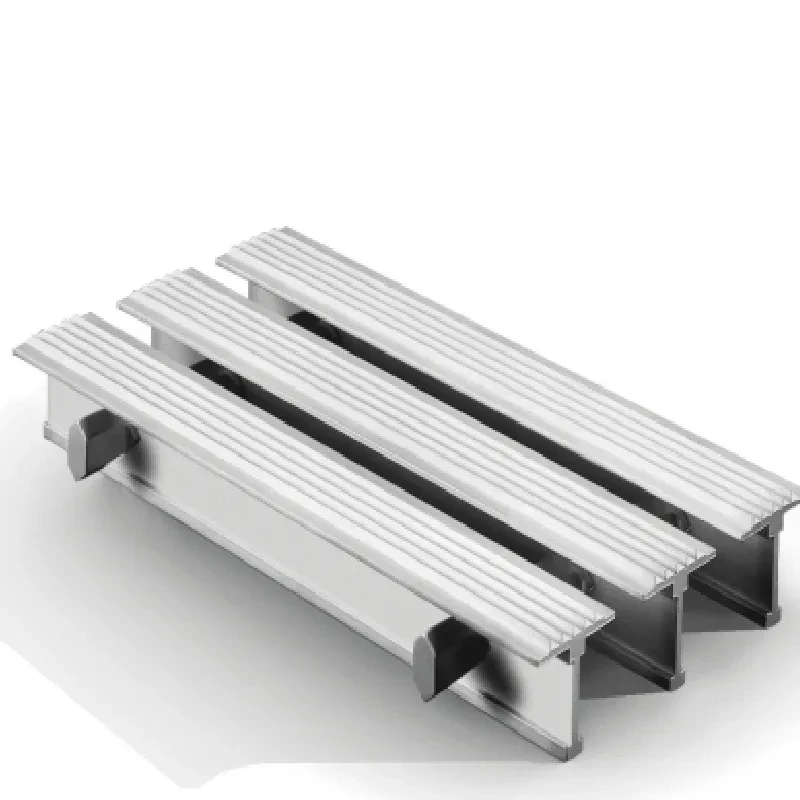

In conclusion, selecting the right aluminum grating supplier is essential for businesses seeking reliable and high-quality products. By focusing on quality assurance, product diversity, customer support, and overall value, organizations can find suppliers that meet their needs effectively. With the right partner, businesses can ensure that their aluminum grating solutions provide safety, functionality, and long-lasting performance, enhancing their operational efficiency and success.